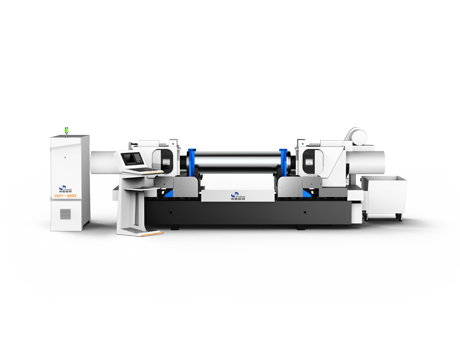

Product introduction

KFQM-20B High-Precision CNC Aspheric Grinder is independently developed by Atoman Science and Technology Ltd. especially to perform shaping and grinding of aspheric glass and resin aspheric lenses or lens moulds. The machine is the primary choice of lens manufacturing. It is capable of providing customers with lens processing solution with the processing software independently developed by the Company.

Features

KFQM-20B High-Precision CNC Aspheric Grinder is equipped with two grinding spindle, capable of rough grinding and precision grinding by grinding wheel for once,with high processing efficiency and easy to operate.

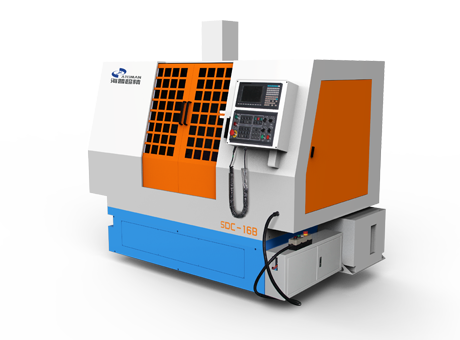

Configurations

● Workpiece axis adopts high-precision high-torque spindle, equipped with high accuracy angle encoder.

● The grinding spindle adopts high-speed grinding spindle with high power.

● Each straight axis adopts imported high-precision linear slider and ballscrew.

● All linear axes are fitted with high-precision linear grating ruler.

● The end of axis is equipped with pneumatic clamp (which can be matched with special clamp of various types).

● Equipped with coolant loop processing system.

● Adopt FANUC CNC system for the control

● The system is equipped with the function of data server, enabling secondary development.

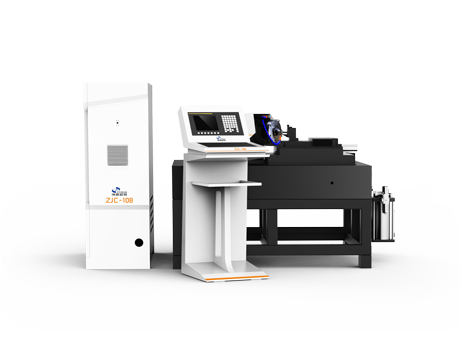

Technical Parameters

1、Rotating accuracy of workpiece principal spindle 2μm

2���、Rotating speed of workpiece principal spindle 0--300rpm

3���、Rotating speed of grinding spindle 180--18000rpm

4����、Z axis (upward and downward movement direction of grinding spindle)

Maximum stroke 320mm

Straightness 3μm / total stroke

5�、X axis (movement direction of workpiece spindle)

Maximum stroke 80mm

Straightness 2μm / total stroke

6、Diameter of parts 50--100mm

Operation Environment Requirements

1��、Oil free. Water free. Atmosphere pressure ≥ 0.6Mpa

2����、Voltage: 380V. Power of instrument: ≤10KW